LED Display Module

Full Color high brightness high refresh rate LED Display module with 3 years Warranty

Catagories

Contact Us

LED Display Panel

High quality full color LED display module with best color uniformity and factory price. we offer all series LED display module with various pixel such as P10mm, P8mm, P6mm, P5mm, P4mm, P3mm, P2mm, P2.5mm, P3.91mm, P4.81mm, etc. Our modules are made with high quality LED chips and driver ICs which ensure the modules is high fresh rate and high greyscale.

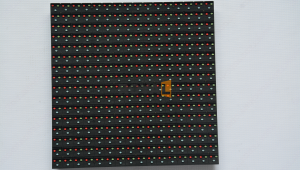

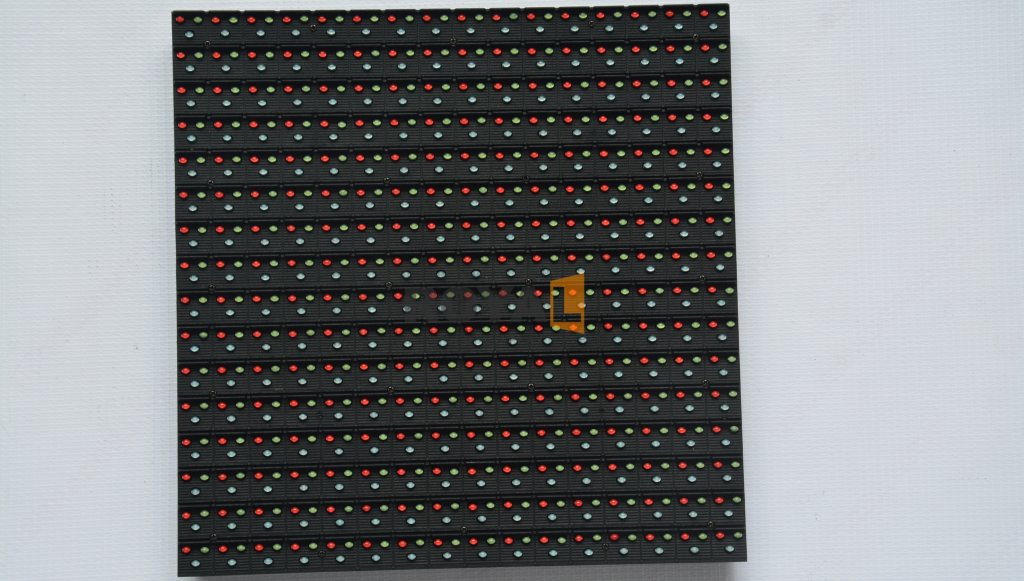

Indoor Module

High Refresh rate RGB SMD indoor LED display module with best color contrast and high greyscale

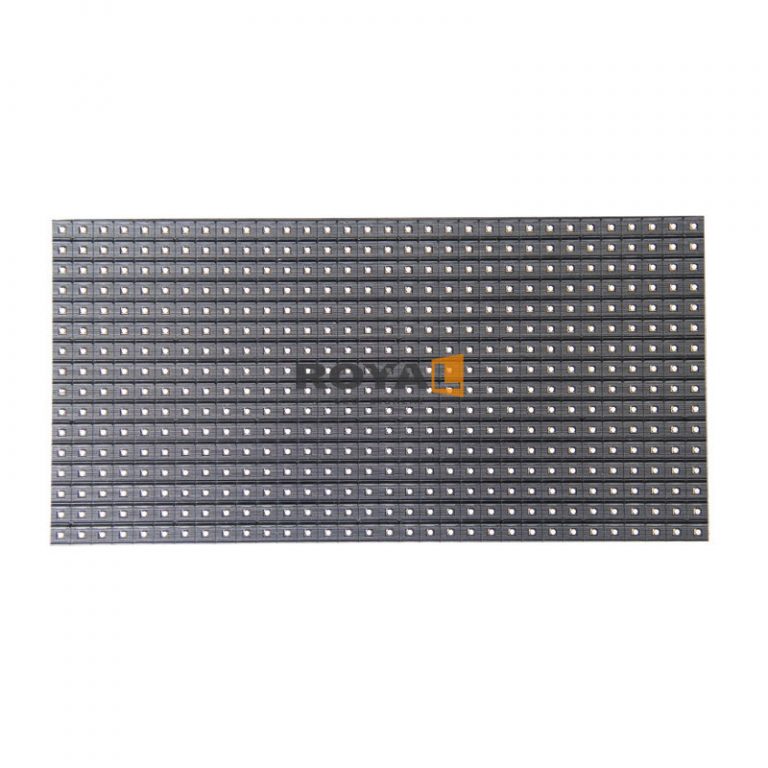

Outdoor Module

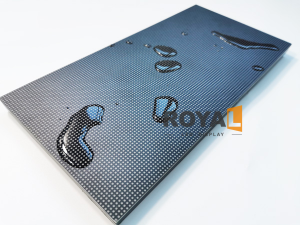

High Brightness outdoor full color LED display module SMD 3in1 LED screen panel with IP65 waterproof level.

DIP Module

Ultra high brightness DIP LED display module for outdoor applications with over 10000nits. P8mm, P10mm, P16mm is available.

Flexible Module

Ultra flexible soft and high refresh rate LED display module for indoor projects. flexible shape for more idears.

Dual Service Module

Dual service LED display module with frontal and rear service. easy and quick installation. High quality with best price.

Aluminum Shell Module

High hardness Die-cast aluminum Aluminum Shell LED display Module with best Flatness and High Precision and long lifespan.

5 Reasons Why You Can't Find the Right LED Display Module

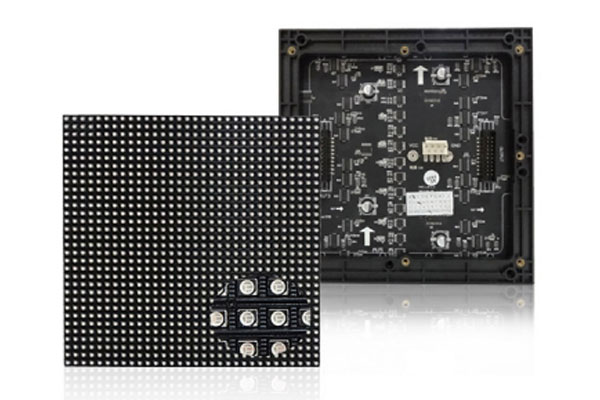

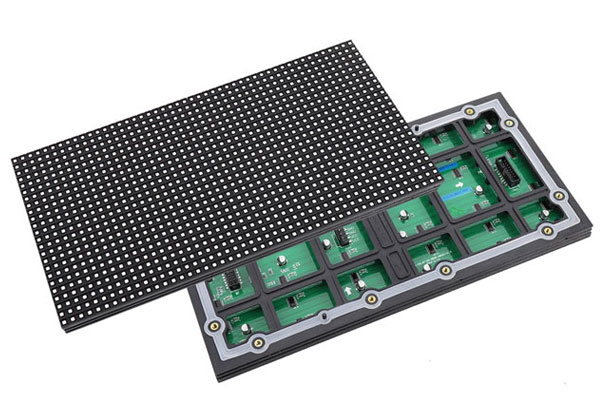

What is LED Display Module?

The LED module is to arrange a certain number of light-emitting diodes together according to the rules and then encapsulates them, plus some waterproof treatment, the product is the LED module.

LED modules are widely used in LED products, and there are also great differences in structure and electronics. A simple module is to use a circuit board and housing with LEDs to become an LED module. Complex modules add some control, constant current source, and related heat dissipation treatment to make LED life and luminous intensity better.

It is mainly used to display the night effect of advertising fonts (acrylic, blister) and logos. It uses text or logo as a medium and installs on the roof or wall of buildings.

It can not only show the daytime effect of the logo but also use LED as a light source to show another effect at night. With LED lighting application control system, dynamic video control of text or logo.

In some places with a strong entertainment atmosphere, LED light source modules have become one of the most important choices for companies to display their self-image.

There are various sizes of LED screen modules, here we list some common sizes: 320*160mm, 250*250mm, 192*192mm, 320*320mm, etc.

Customers can choose different sizes to build LED screens with different scales.

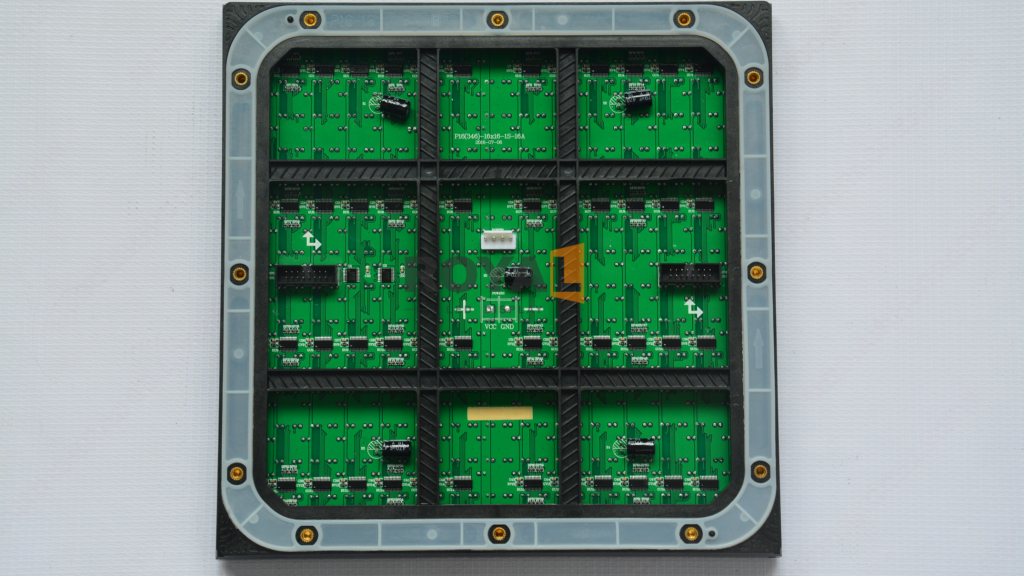

1、The Structure of LED Display Module

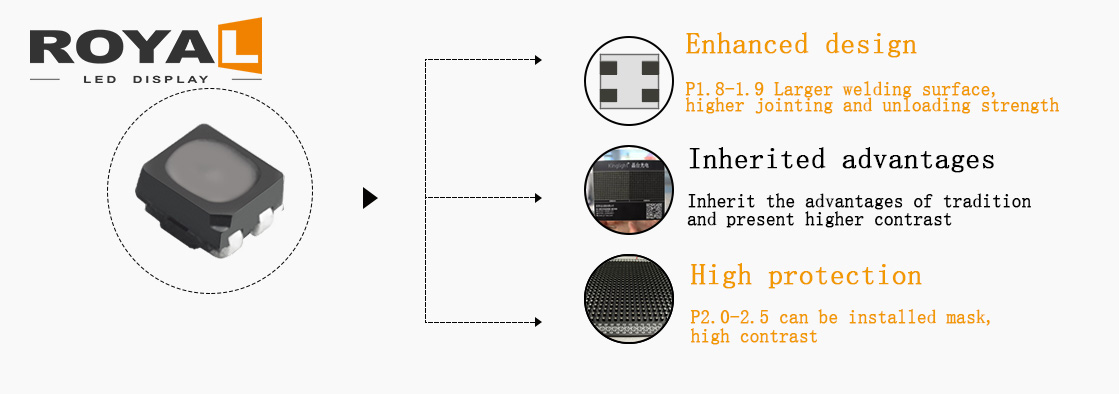

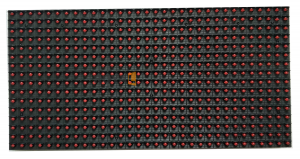

1.1 LED lamp beads

The most important part of the module is also responsible for reproducing the image. Each square meter of LED screen module can place thousands of LED lamp beads, and their number determines the clarity and pixel pitch.

In short, LED lamp beads have a crucial impact on the screen in many aspects: viewing angle, brightness level, luminous rate, lifespan, consistency, etc.

Common brands include Nation Star, Kinglight, and HongSun.

The following are some common models of SMD LED lamp beads: SMD2727, SMD2020, SMD3535, and SMD1515 (the model name is determined by the size of the lamp bead).

Generally, there is a positive correlation between size and brightness level.

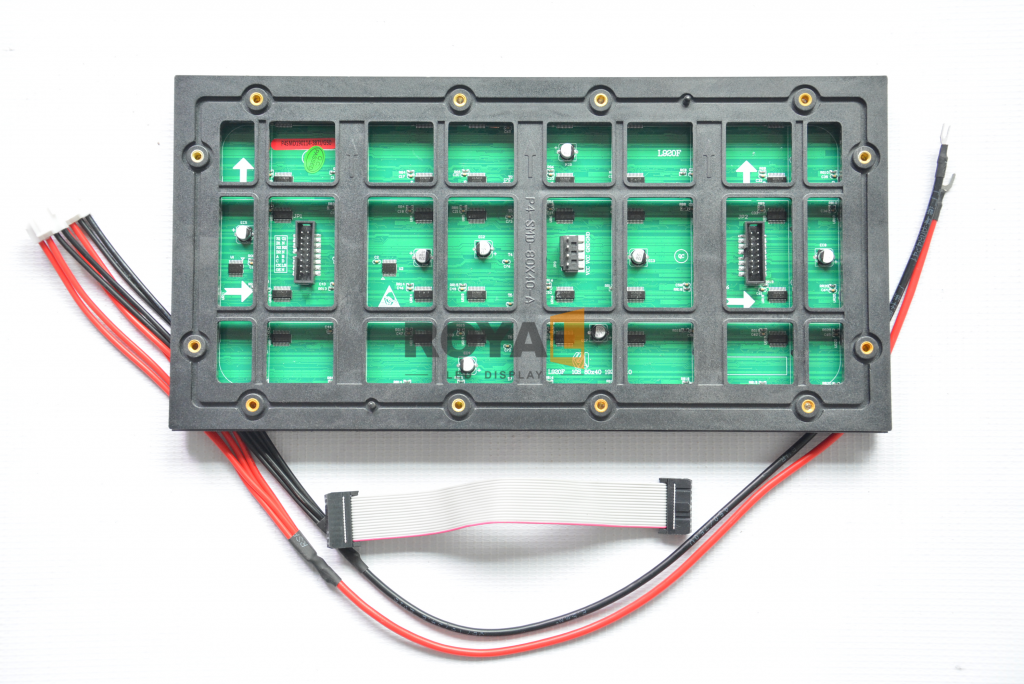

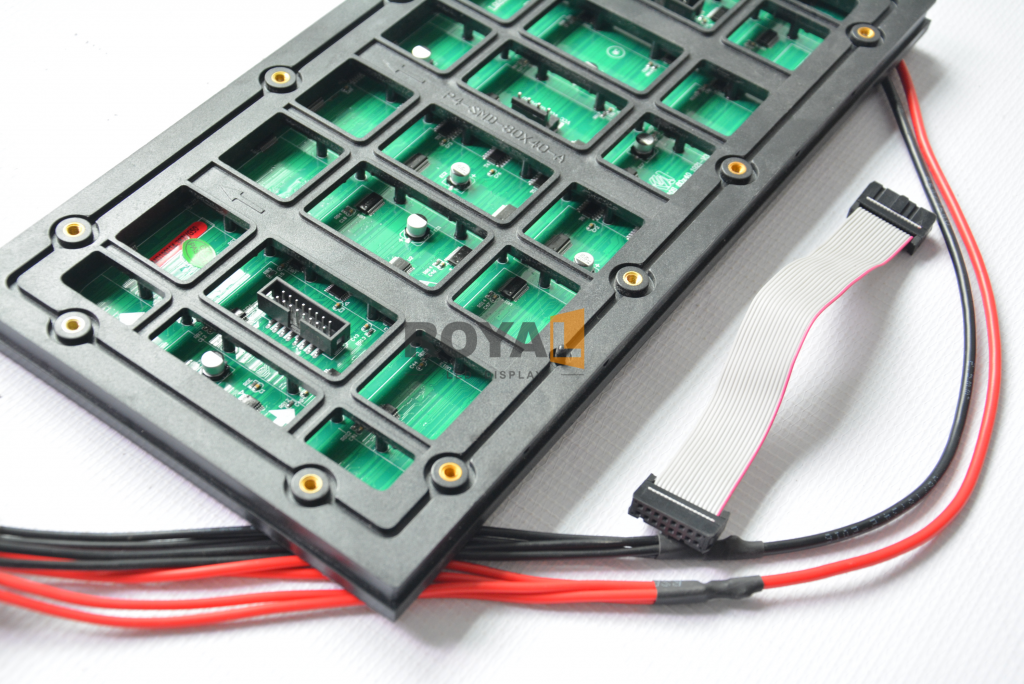

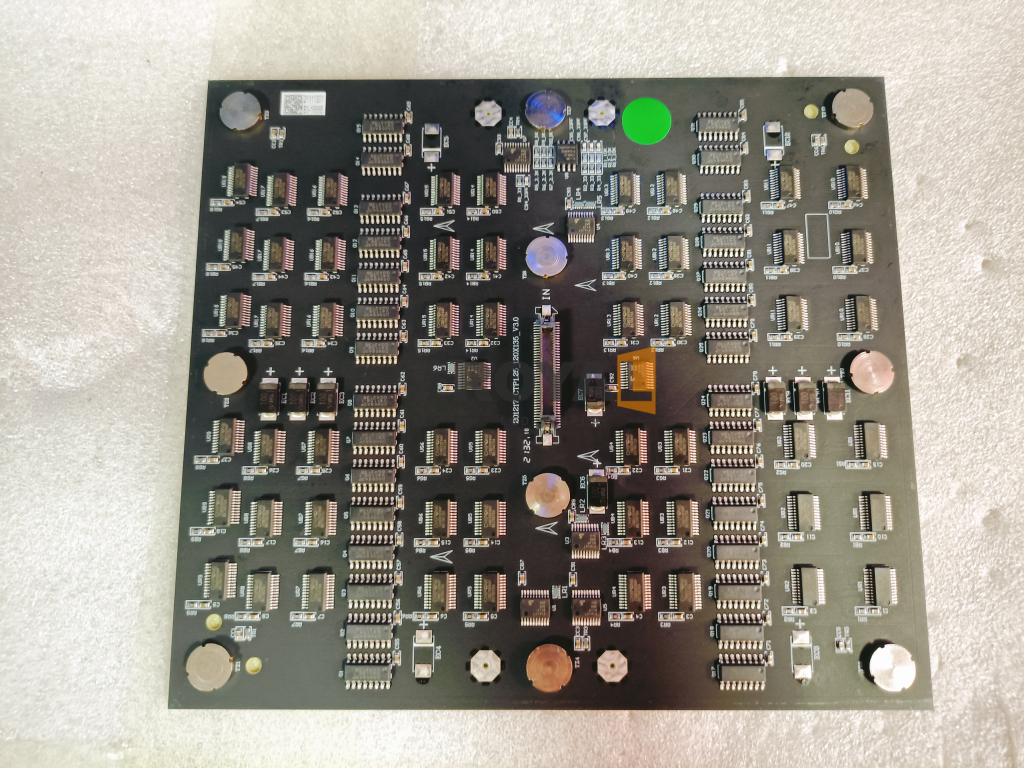

1.2 PCB board

The PCB board is the printed circuit board on which the IC drivers and lamp beads and other electronic devices will be equipped. The upper copper conductor tracks interconnect it with other components.

Inserting LEDs on the front side of the PCB board and assembling ICs (chips or integrated circuits) on the back side can be used to manage color, brightness, images, etc.

1.3 IC driver

The IC driver distributes power and signals to the LED lamp beads, and determines the scanning mode according to the number of lamp beads controlled by a single pin.

One of the most important functions of an IC chip designed for an LED display is to provide a constant flow source to achieve stable visual performance of the LED screen, such as avoiding constant light flickering.

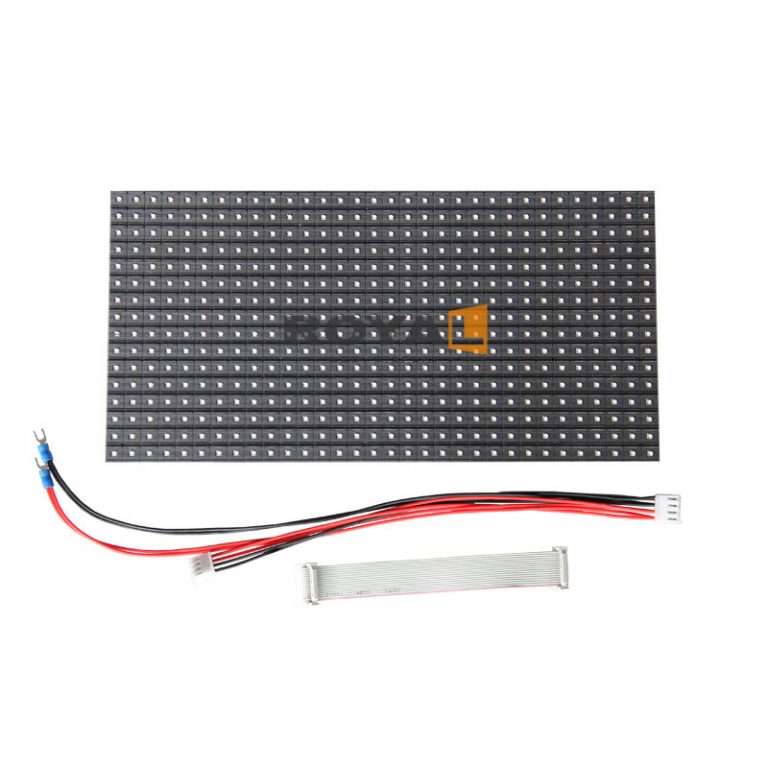

1.4 Cables: Flat cables and power cords

Cables carry signals and power between LED modules, connecting them together.

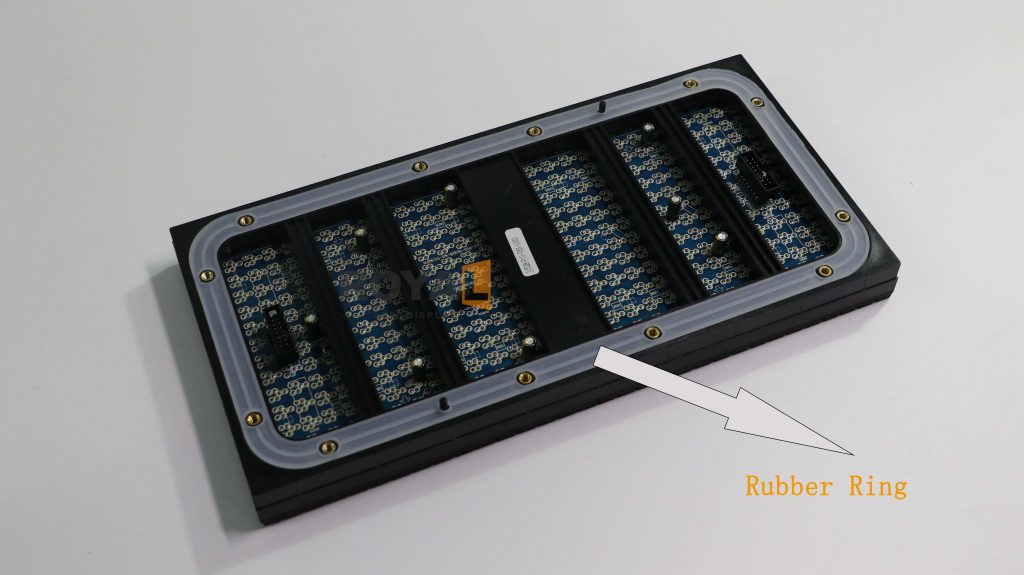

1.5 Rubber band

The rubber ring is mainly used to improve the waterproof ability.

For outdoor LED display, the rubber ring can avoid water ingress.

1.6 Mask

The black plastic front case has a number of holes that match the LED locations.

For outdoor screens, visor-style ledges on each LED improve their visibility in direct sunlight.

2. Classification of LED Display Modules

2.1 Divided by luminous color

LED display modules are divided by color.

① Monochrome modules, such as single red, single green, single blue, single yellow, and single white modules.

② Two-color modules such as red and green two colors, red and blue two colors.

③ The full-color module mainly uses red, green, and blue three primary colors of a LED module.

2.2 Divide by the places

LED display modules are divided into indoor LED display modules, semi-outdoor LED display modules, and outdoor LED display modules according to the different use places.

2.3 Divided by the use of lamp beads

According to the different LED packaging devices, LED display modules are divided into in-line LED display modules, indoor dot matrix LED display modules, and surface mount LED display modules.

2.4 Divided by the pixel spacing

According to the LED pixel spacing, indoor LED display modules can be divided into P2.5 LED module, P3 LED module, p4 LED module, p5 LED module, P6 LED module, p7 LED module, p8 LED module, etc.

And outdoor LED display modules can be divided into p10 LED module, p12 LED module, p16 LED module, p20 LED module, P25 LED module, etc.

3. Five Types of LED Display Modules

DIP package is the abbreviation of the dual inline-pin package, commonly known as a plug-in display.

It is the first developed among the three encapsulation modes. Lamp beads are produced by LED lamp bead packaging manufacturers and then inserted into LED PCB light boards by LED module and display manufacturers. After wave soldering, DIP semi-outdoor modules and outdoor waterproof modules are produced.

- The price is affordable, with many uses and a large market.

- Low power and energy saving.

- Long service life and good luminescence.

- The product is of good quality, durable, and not easy to break.

At present, the production organization of DIP displays is relatively complicated. It is not easy to implement mechanized production, and production efficiency is low.

The quality of the display screen is subject to the quality of the lamp beads of the lamp bead packaging factory. It is not easy to control each batch, so the quality is not well controlled.

In addition, there are many DIP manufacturers, there is no high technology and equipment threshold, so the competition is fierce. Many manufacturers use inferior raw materials and PCB boards to reduce costs to gain market share. The quality is low, and there is almost no perfect after-sales guarantee.

3.2 SMD LED Display Module

The surface mount LED lamp beads are mainly in the shape of a cube or cuboid. The packaging process is to fill the chip into a metal bracket, then pour glue and dry it.

The specifications are SMD 3535/SMD 3528/SMD 2835/SMD 2727(2525)/SMD 2121/SMD 1921/ SMD 1515/SMD 1010 and many other types.

The packaging technology is mature, and the light-emitting surface is single-side light-emitting.

- Can make displays thinner, brighter, and clearer than LCD

- The power consumption is 10/1 of the LCD display

- High brightness

- Viewing angle 160°

- High refresh rate, contrast ratio, better display screen, and better product performance

- It can be viewed under strong light

- The reaction of a single element is 1000 times that of the LCD screen

- It can also be used at temperatures between -30°C and 80°C

- Waterproof, moisture-proof, anti-static, dust-proof, lightning-proof, anti-static

- There are many types of spacing, and suitable for various environments

- Various shapes can be spliced arbitrarily

- Long lifespan (more than a decade)

- The brightness is too high, and it is easy to fatigue the eyes when watching for a long time.

- There is graininess when viewed at close range

- The lamp beads may be damaged during transportation.

- The heat dissipation capacity is not strong enough

- There is a big difference between the spacing

- Difficult to clean

3.3 COB LED Display Module

Chip On Board (COB) The full name of the COB package is Chips on Board (COB), which is a technology to solve the problem of LED heat dissipation.

It is to adhere the bare chip to the interconnect substrate with conductive or non-conductive glue, and then wire bond to achieve its electrical connection.

- Small spacing, smooth screen, clearer display (preferred below P1.0)

- The picture is bright, and it does not hurt the eyes when watching for a long time.

- The contrast ratio is 10000:1, the picture quality is better

- Refresh rate ≥ 3840Hz, a symbol of high quality among similar products

- Anti-collision, the load-bearing capacity is more than 5 times that of the LED display, and it is not afraid of collisions and broken lights during transportation.

- Good heat dissipation capacity, heat can be quickly dissipated directly through the PCB board

- Effectively suppress moiré

- Large viewing angle of 170°

- Waterproof, moisture-proof, anti-static, dust-proof, lightning-proof, anti-static, anti-collision

- It can also be used at temperatures between -40°C and 80°C

- Easy to clean

- Long lifespan (more than a decade)

- The price is high

- The technology of each enterprise is uneven

- The appearance of the screen is not as good as the small spacing of LEDs

- The production process is different from SMD packaging, and the cost of transformation is high

3.4 GOB LED Display Module

It is mainly used for outdoor LED rental displays and indoor small-spacing displays. A technology for filling the lamp surface with glue, so the surface of the display is waterproof, dustproof, and impact-proof.

A simple click you will get to know more about GOB LED display module

- Waterproof, moisture-proof, bump-proof, dust-proof, anti-corrosion, anti-blue light, anti-salt spray, and anti-static.

- Due to the matte surface effect, the color contrast is also increased, the conversion display from the display point light source to the surface light source is realized, and the viewing angle is increased.

- As a typical LED display, the SMD LED display used in bracket packaging technology needs to continue to strengthen to solve all existing technical problems, such as better heat dissipation

- It can further improve the performance of the glue, and improve the bonding force and retardation.

- The outdoor transparent LED display has no reliable outdoor protection and anti-collision ability.

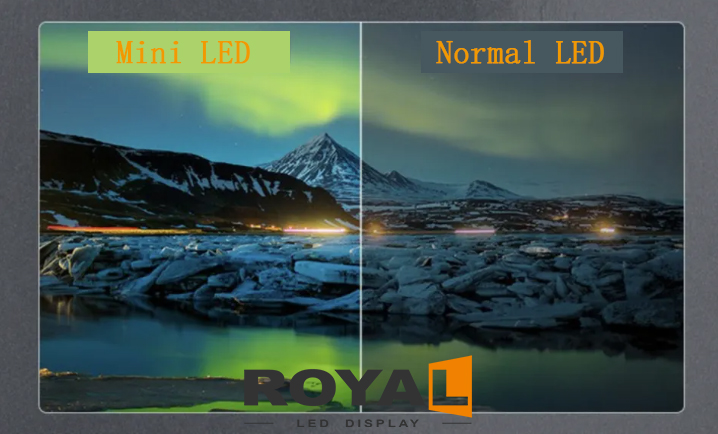

3.5 Mini LED Display Module

MiniLED is a backlight technology for LCD screens.

This kind of technology is easy to understand. In the past, the screen backlight was a single block. When we turn on the screen, the entire screen will be on. When we turn it off, the whole screen will go out.

The MiniLED screen backlight is composed of many lamp beads. So the part of the module that needs to be lit is turned on, and the part that does not need to be lit can be turned off.

Simply put, it is through the LED backlight technology that the single volume becomes smaller, the overall number is greatly increased, and the switch can be independently controlled.

- High resolution

- High contrast

- High brightness

- Color Accuracy

- Slow response time

- When displaying a small-scale image, there will be halos and yellowing, etc.

- If the heat is too high, some products will install fans inside to assist heat dissipation, which will generate noise

- PWM dimming can hurt the eyes

4.LED display module installation precautions

- Special switching power supply for LED: The power supply can only be moisture-proof, not waterproof, so the external power supply must be waterproof.

- The output voltage of the switching power supply is adjusted according to the characteristics of the LED module. Please do not rotate the voltage adjustment button at will during use.

- The LED modules all use low voltage input, and the power supply needs to be installed within 10 meters of the LED light-emitting module.

- LEDs have positive and negative poles. When installing, pay attention to the positive and negative poles of the power port wiring. If the positive and negative poles are reversed, the module will not emit light, nor will the LED module be damaged.

- The LED module adopts low voltage input, so it must be directly connected to 220V without going through the power supply, otherwise the whole module will be burned.

- When installing the LED module, it is required to use double-sided tape or woodworking glue, so that the module slot and the plastic bottom plate are firmly attached. When using double-sided tape, it is necessary to add glass glue, otherwise, the module will fall off when exposed to sunlight for a long time outdoors.

5.Conclusion

The functions of LED display modules are not only diverse and reliable but also have excellent visual performance.

It is cost-effective and energy efficient, so the LED display module will be your perfect choice.

Royal Display provides customers with high-quality LED display modules and services!

Just fill in the simple form to contact us now, and you will be able to get the best price quotation and unimaginable module products!

Get You Quote Now

With Excellent Products As The Source, Royal Display Factory As The Foundation, Continue To Offer ODM&OEM Service For 10 Years. Please feel free to contact us at any time, we will respond to you in 24 hours.