GOB LED Display Module

Home » GOB LED Module

GOB LED Screen Panel

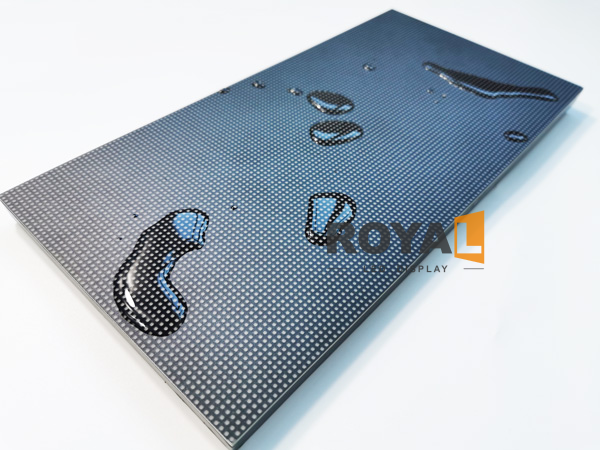

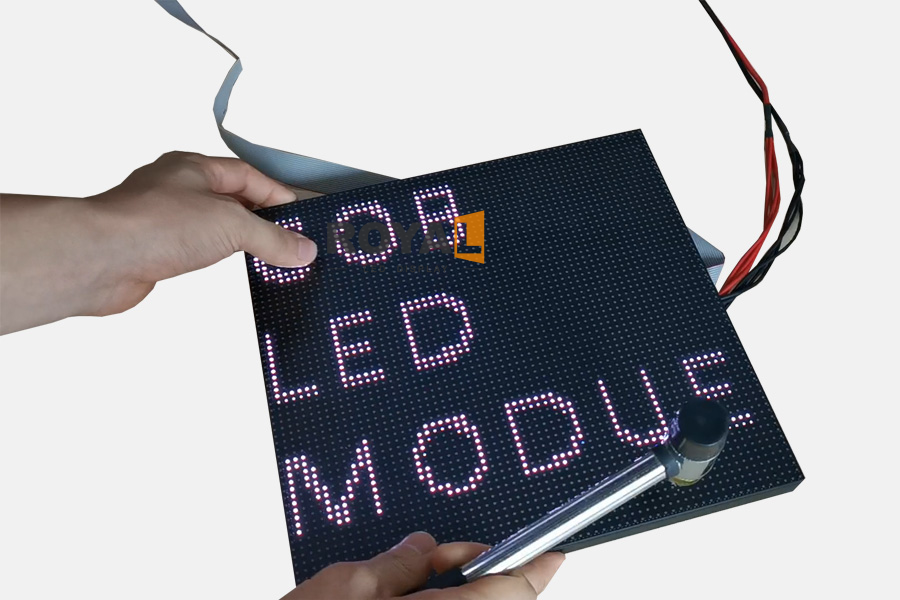

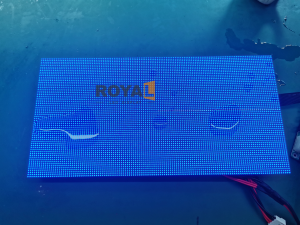

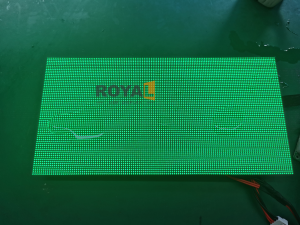

High Waterproof high protection GOB LED display module with factory price and best color uniformity.

we choose High-Quality Nationstar/Kinglight/Hongsen LEDs from LED Lamps Factory directly which have high color contrast and best color uniformity so as to meet the need for high grayscale and keeping natural color

Key Features

High Dust-Proof Level

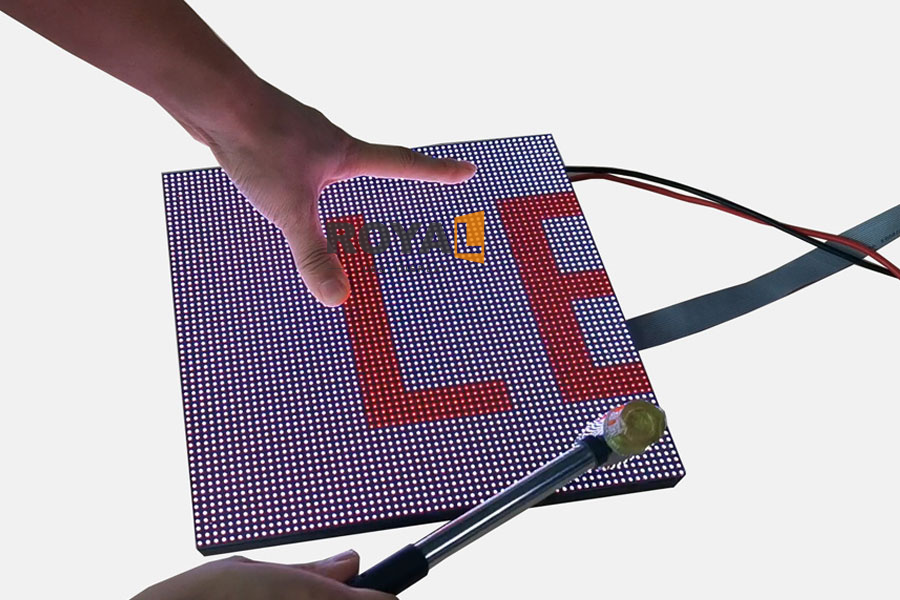

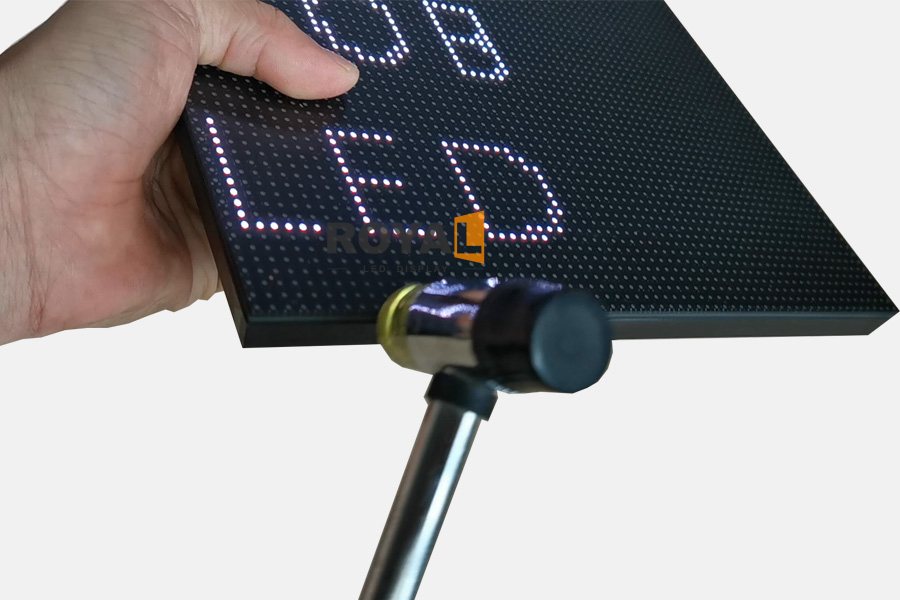

High Shockproof Level

High Waterproof Level

Better Color Uniformity

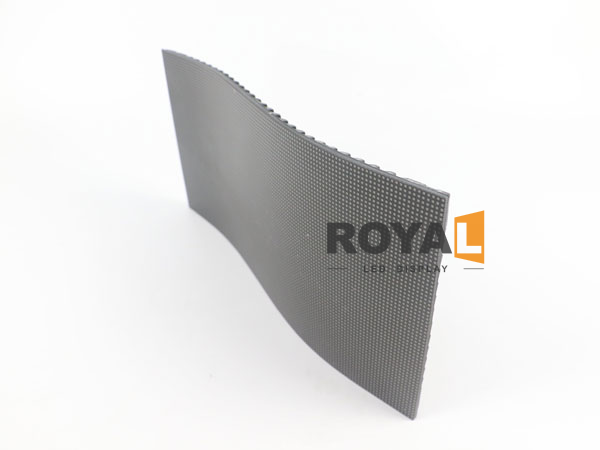

Flexible GOB LED Panel Available

- SMD 3 in 1

- High Greyscale

- High Refresh Rate

- CE,RoHS,FCC Approved

- 2 Years Warranty

High Waterproof Level

High Shockproof Level

Special-designing dash-proof glue able to have shock-proof function, offering ultra high protection for LEDs in the various impacts.

High Dust-Proof Level

Flexible GOB LED Panel Available

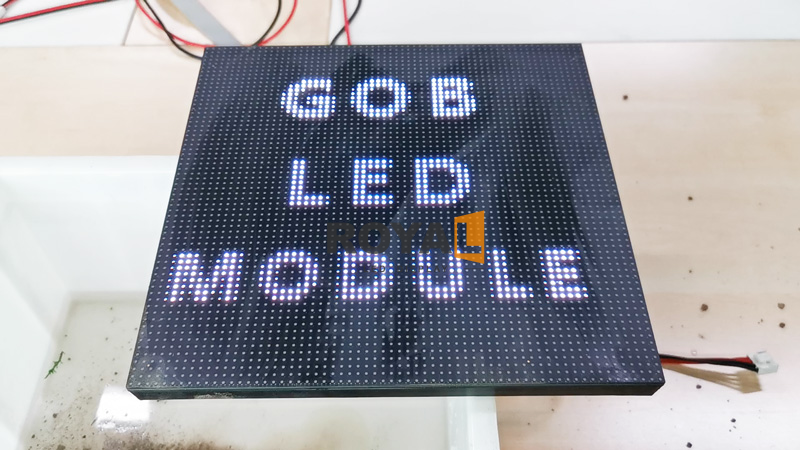

Excellent Visual Effect

With high qualiyt LEDs and driver ICs, the GOB LED module can offfer

excellent visual experience in many installation applications.

GOB LED Display Module Specification

| Type | Pixel Pitch | LED | Module Resolution | IC Number | Brightness(Nits) | Module Size(MM) | Driving Mode |

| 320X160 Series | P1.25mm | 1010 (Black LED) | 256*128 | 96 | 600-800 | 320*160 | 1/64Scan |

| P1.538mm | 1010 (Black LED) | 208*104 | 84 | 600-800 | 320*160 | 1/52Scan | |

| P1.667mm | 1010 (Black LED) | 192*96 | 72 | 600-800 | 320*160 | 1/64Scan | |

| P1.839mm | 1515 (Black LED) | 174*87 | 52 | 600-800 | 320*160 | 1/58Scan | |

| P1.86mm | 1515 (Black LED) | 172*86 | 66 | 600-800 | 320*160 | 1/43Scan | |

| P2mm | 1515 (Black LED) | 160*80 | 60 | 600-800 | 320*160 | 1/40Scan | |

| P2.5mm | 2121 (Black LED) | 128*64 | 48 | 800-1000 | 320*160 | 1/32Scan | |

| P3.076mm | 2121 (Black LED) | 104*52 | 42 | 800-1000 | 320*160 | 1/26Scan | |

| 250X250 Series | P2.604mm | 1515 (Black LED) | 96*96 | 54 | 800-1000 | 250*250 | 1/32Scan |

| P2.976mm | 2121 (Black LED) | 84*84 | 54 | 800-1000 | 250*250 | 1/28Scan | |

| P3.91mm | 2121 (Black LED) | 64*64 | 48 | 800-1000 | 250*250 | 1/16Scan | |

| 240*240 Series | P1.875mm | 1515 (Black LED) | 128*128 | 48 | 800-1000 | 240*240 | 1/64Scan |

| P2.5mm | 2121 (Black LED) | 96*96 | 54 | 800-1000 | 240*240 | 1/32Scan | |

| Other Series | P2mm | 1515 (Black LED) | 128*64 | 48 | 800-1000 | 256*128 | 1/32Scan |

| P2.5mm | 2121 (Black LED) | 64*64 | 24 | 800-1000 | 160*160 | 1/32Scan | |

| P3mm | 2121 (Black LED) | 64*64 | 24 | 800-1000 | 192*192 | 1/32Scan |

Ultimate Guide of GOB LED - 7 Things You Need to Know

Part 1 – What is GOB Technology?

Part 2 – What is the difference between COB, GOB and SMD

Part 3 – Advantages and disadvantages of COB, SMD and GOB LED displays

3.1、The advantages and disadvantages of COB

3.2、The advantages and disadvantages of GOB

3.3、The advantages and disadvantages of SMD

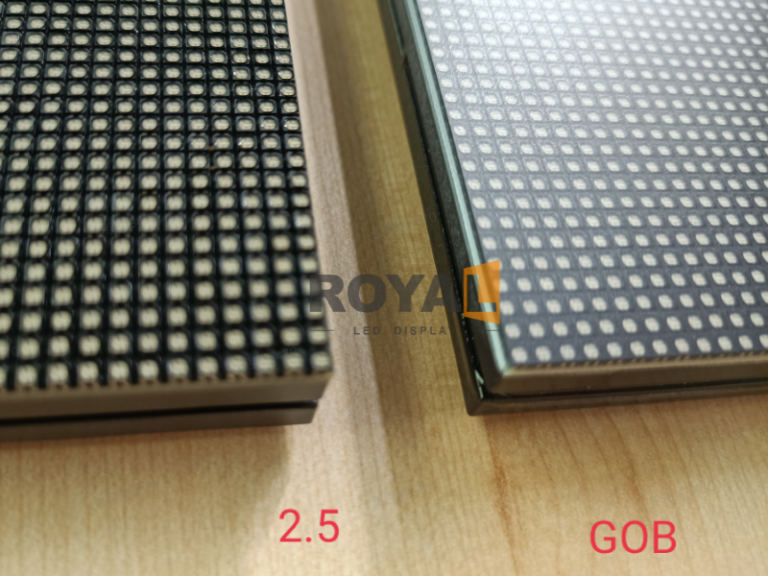

Part 4 – Difference between GOB module and traditional module

Part 5- Why GOB LED technology is better for you

Part 6 – How to make a high quality GOB LED display?

Part 7 – Applications of GOB LED Screens

Even if the development of LED display technology for a long time, there are still difficult points to be improved. Waterproof performance, for example, even if an IP rating of more than 70, only reduces the failure due to rain erosion, and can not solve the root cause of the solution to the waterproof problem.

Based on this problem, a new surface super-protection technology called GOB LED display modules on the market came into being. Its high-performance protection technology, as well as the delicate display effect, has also been quickly recognized by the industry in just a few years, becoming a new generation of technology in the LED display industry in the past two years. And attract many companies to join the GOB technology industry, research and development, and production of a new generation of GOB products to expand the LED display protection market.

Part 1 - What is GOB technology?

GOB is the abbreviation of GLUE ON BOARD, GOB process is a kind of double surface optical treatment of conventional LED display PCB board and its SMD lamp beads by using new optical and thermal conductive nano-fill material, encapsulated and matte by a special process.

It is LED display with high protection against impact, dust, water, moisture, and UV rays, and will not have harmful effects on heat dissipation and brightness loss.

Rigorous tests over a long period of time have shown that the shielding adhesive even helps to dissipate heat, thus extending the service life.

It realizes the matte effect of LED display surface, enhances the existing LED display protection technology, and innovatively realizes the transformation of display point light source from the surface light source, which has a broad market in the fields of small pitch display, high-end rental, commercial display and household “LED TV”.

Let’s feel the charm of GOB through the video.

It is also suitable for flexible LED displays and offers excellent flexibility for precise screen mounting depending on the building’s structure.

Part 2 - What is the difference between COB, SMD, and GOB

What is COB?

COB package is called Chips on Board (COB), which is a technology to solve the problem of LED heat dissipation. Compared with in-line and SMD, it is characterized by space-saving, simplified packaging operation, and efficient thermal management.

The bare chip is attached to the interconnection substrate with conductive or non-conductive adhesive, and then lead bonding is performed to achieve its electrical connection.

If a bare chip is directly exposed to air, it is susceptible to contamination or human damage, which affects or destroys the function of the chip, so the chip and bonding leads are encapsulated with adhesive.

People also call this form of packaging the soft package seal. It has certain advantages in terms of production and manufacturing efficiency, low thermal resistance, optical quality, application, and cost.

What is SMD?

SMD stands for Surface Mounted Devices, which is one of the SMT (Surface Mount Technology) components. In the initial stages of electronic circuit board production, over-hole assembly was done entirely by hand.

After the first automated machines were introduced, they could place some simple pin components, but complex components still needed to be placed by hand before reflow soldering. Surface Mounted components are mainly rectangular chip components, cylindrical chip components, composite chip components, and shaped chip components.

What is GOB?

We have already talked about the technical principles of GOB before, so we won’t go into details here.

Part 3 - Advantages and Disadvantages of COB, SMD, and GOB LED display

1.Advantages and disadvantages of COB

1、Dot pitch can be made smaller

The feature of COB package technology is that it can reduce the distance between the LED beads. The original SMD package LED screen’s minimum point space is P1.2, that is, 1.2mm. If it continues to become smaller, it is difficult to achieve and can not guarantee a certain range of dead light rate.

The COB package has changed the arrangement and composition of the LED beads, so it can make the point spacing smaller.

2、 Better protection performance

In the process of transportation and installation, some small pitch LED displays, but a little collision will have the lamp beads off. This causes individual pixel dead light, not luminous, or only displays monochrome, which has some reasons with the packaging technology.

With the introduction of the COB package, the situation has become much better. As the COB package is a directly encapsulated LED chip in the PCB board concave lamp slot, and then fixed with epoxy resin. So the whole lamp ball is a raised sphere, and the overall is smooth and hard, so the protection performance is better.

3、Longer life, low dead light rate

COB products are encapsulated in the PCB board, and through the PCB board copper foil will quickly transfer the heat of the wick, and the PCB board copper foil thickness has strict process requirements, coupled with the sinking process, which may not cause serious light attenuation.

So rarely dead lights, greatly extending the life of the LED display.

1、The finished product is more difficult to manufacture

COB package to ensure that each lamp is not a problem before filling the glue, it can not be like an SMD package as a separate replacement of a lamp bead, so the requirements for the entire packaging process are very high.

2、Inconvenience of maintenance

Like the traditional SMD package of LED beads, if there are dead lights, you can disassemble the unit board after the individual beads can be repaired by welding. If this repair of COB package products will affect the surrounding lights, maintenance is very difficult.

Although it is better protection, there will be a certain rate of dead lights, but the chances will be lower, in this case, can only replace the unit board, so the cost is higher.

2.Advantages and disadvantages of SMD

1、High assembly density, the small size of electronic products, lightweight, SMD components of the volume and weight of only about 1/10 of the traditional cartridge components.

After the general use of SMT, electronic products reduce the volume by 40% to 60%, and weight reduction by 60% to 80%.

2、High reliability, strong vibration resistance. Low defect rate of solder joints.

3、Good high-frequency characteristics. Reduced electromagnetic and radio frequency interference.

4、Easy to realize automation and improve production efficiency. Reduce cost up to 30%~50%. Save material, energy, equipment, manpower, time, etc.

1、Module protection needs to be further strengthened

2、Mask can be sensitive due to environmental changes

3.Advantages and disadvantages of GOB

1、 High Protection Capability

The most outstanding feature of GOB LEDs is the high protection capability, which effectively protects the display from water, humidity, UV, impact, and other risks.

This feature can avoid massive dead pixels and broken pixels.

2、Advantages of COB LEDs

Compared to COB LEDs, it is easier to maintain and has lower maintenance costs.

In addition, the viewing angle is wider and can reach 180 degrees both vertically and horizontally.

In addition, it can solve the problems of poor surface flatness, inconsistent color, and high scrap rate of COB LED display.

3、It is suitable for applications where people can easily access the screen.

As a protective layer covering the surface, it can deal with unnecessary damage caused by people, such as the problem of falling light beads, especially LED lights placed in the corners.

GOB LED displays can be used in the following scenarios: elevators, shopping malls, fitness rooms, auditoriums, conference halls, live performances, subways, events, studios, concerts, etc.

4、Suitable for fine-pixel LED displays and flexible LED displays.

This type of LED is currently used in small PP LED screens with a pixel pitch of P2.5mm or less, and also for LED displays with high pixel pitch.

In addition, it is compatible with flexible PCB boards and can meet the high requirements of highly flexible and seamless displays.

5、High contrast ratio

Since the surface is matte, the contrast of colors is improved, which increases the playback effect and expands the viewing angle.

6、Friendly to the naked eye

It does not emit ultraviolet and infrared rays, nor does it emit radiation, which is safe for people’s naked eyes.

In addition, it protects people from “blue light hazards” because blue light has a short wavelength and high frequency, which may cause damage to people’s eyesight if viewed for a long time.

And it uses materials from LED to FPC that are environmentally friendly and recyclable and will not cause pollution.

1、As a typical LED display applied to the SMD LED display in the holder packaging technology, to solve all existing technical problems, such as better heat dissipation, there is a need to continue to strengthen

2、The performance of the glue can be further improved to improve the adhesive force and retardation.

3、Outdoor transparent LED display does not have reliable outdoor protection and anti-collision capability.

Now we know the difference between the three common LED screen technology, GOB has all kinds of advantages in your mind, and it also includes the advantages of SMD and COB.

Part 4- Difference between GOB module and traditional module

GOB Integrated Module | Conventional non-glued modules | |

Waterproof | At least IP68 to achieve true waterproof | Not available |

Dustproof | At least IP68 to achieve true dustproof | Not available |

Anti-vibration | Good anti-vibration performance | Poor anti-vibration performance |

Anti-oxidation | At least IP68 to achieve true anti-oxidation | Does not have |

Moisture resistant | Can be moisture resistant under temperature difference or pressure conditions | The lamp and PCB will absorb moisture in a few months and a large number of dead lights will appear |

Installation, moving, transportation | In the installation, handling, transportation process will not lead to the module or the edge of the box lights touch broken, not to mention the phenomenon of falling lights | In the installation, handling, transportation process can easily lead to the module or box of the light touch broken and dropped lights phenomenon occurs |

For the eyes | Long time viewing is not harsh, not fatigue, can protect the eyes | Long time viewing harsh, fatigue, can not protect the eyes |

Viewing angle | Whatever the conditions of white balance and video playback, vertical and horizontal 180 ° no dead angle | High temperature conditions in the horizontal angle of 160 ° or less, with the temperature rises, the mask bulge, the angle of about 140 °, the upper and lower angle can not reach 120 ° |

Service life | Light performance is not subject to environmental factors, the normal service life | Lamp performance by environmental factors, service life greatly shortened, PCB performance by environmental factors, copper ion migration, resulting in micro-short circuit |

Surface cleaning | Can be cleaned on the surface | After a period of time (half a year), the surface dent of the mask is full of dust and white, can not be cleaned |

Part 5 - Why GOB LED technology is better for you

The GOB process solves industry difficulties

1、Low protection level: not moisture-proof, waterproof, dustproof, shockproof, anti-collision. In a humid climate, it is easy to appear in large batches of dead lights, and bad lightss phenomenon.

In the process of transportation, it is easy to drop the lights and bad lights. Also easy to be affected by static electricity, causing the phenomenon of dead lights

2、Eye damage: prolonged viewing will appear blinding, fatigued, and can not protect the eyes. In addition, there is a “blue harm” impact, because the blue LED wavelength is short, and high frequency, and the human eye directly, long-term exposure to blue light, easy to causes retinopathy.

3、Improve the consistency of the ink color

GOB improves the consistency of ink color on the screen surface, making the color and brightness more uniform.

4、Excellent matte effect

PCB board and SMD lamp beads can achieve a great matte effect on the screen surface after double optical treatment.

This can increase the contrast of the display to perfect the final image effect.

5、Wider Viewing Angle

Compared to COB LEDs, GOB extends the viewing angle to 180 degrees, allowing more viewers to reach the content.

6、Excellent Surface Uniformity

The special process ensures excellent surface uniformity, which contributes to high-quality display.

7、Fine Pixel Pitch

GOB displays are more suitable for HD images and support pixel pitch below 2.5mm for P1.6, P1.8, P1.9, P2, etc.

So, what are our criteria for choosing the right GOB LED?

Part 6 - How to make a high-quality GOB LED display?

The GOB process has to pass six levels, material level, fill level, thickness level, surface level, and maintenance level.

6.1 Material Level

GOB packaging materials must be with the GOB process program development of customized materials, and must meet the following characteristics:

1、strong adhesion

2、strong resistance to tension and vertical impact

3、hardness

4、high transparency

5、temperature resistance

6、yellowing resistance

7、salt spray resistance

8、high abrasion resistance

9、anti-static

10、high-pressure resistance, etc

6.2 Filling Level

The GOB packaging process ensures that the packaging material fills the gap and covers the surface of the lamp beads, and PCB is closely bonded. There can be no bubbles, air holes, PCB, glue bonding surface flooding white spots, or cavities, not filled with such phenomena.

6.3 Thickness Level

The thickness consistency of the glue layer (accurately described as the consistency of the thickness of the glue layer above the surface of the lamp bead), after GOB packaging, must ensure the uniform consistency of the thickness of the glue layer above the surface of the lamp bead.

At present, the GOB process has been fully upgraded to 4.0, with almost no more rubber layer thickness tolerance. The thickness of the original module is the same as the thickness after it is done. Even the original module thickness can be reduced after it is done. And Splicing flatness is quite perfect!

The consistency of the thickness of the adhesive layer is crucial to the GOB process, but can not guarantee the modularity of the black screen and lit state, splicing screen, uneven splicing height, poor color consistency, and a series of fatal problems.

6.4 Leveling Level

The surface flatness after GOB encapsulation should be pretty good, and there should be no pits, undulations, etc.

6.5 Surface Level

GOB package surface treatment.

According to different product characteristics, the industry surface treatment is divided into the matte surface, and mirror surface.

6.6 Maintenance Level

GOB encapsulation after the repairability.

Ensure that the packaging material is easy to take off under specific conditions.

And after repair, the removed part can be refilled.

Part 7 - Applications of GOB LED Screens

7.1 Types of display GOB LED modules that can be used.

① Interactive LED display

② Rental LED display

Since it is a rental LED display, it needs to be installed and dismantled frequently. But usually, this process may damage the LED enclosure and cabinet, thus increasing the maintenance cost.

GOB LED displays can solve this key point precisely, thus saving money and time.

③ Poster LED display

Poster-style LED displays are usually placed indoors, so people can easily damage their surfaces, increasing the risk of damage.

GOB LED module has stronger surface protection from knocking and crushing of the screen.

For indoor poster LED screens, it is definitely a more suitable one.

④ Flexible LED display

Flexible GOB LEDs can be widely used to make LED video cylinders of various diameters.

Because of the enhanced protection, it can be bent 360 degrees.

A flexible GOB LED display would be an excellent choice when customers want to create a reliable, novel flexible display.

⑤ Fine pixel pitch LED display

⑥ Floor LED display

GOB LED screen can replace the acrylic cover layer of traditional floor LED screen. And it has better light transmission and visual effects.

By adding just a few simple structures, GOB LED screens can be used as floor screens without the need for glue protection like traditional LEDs.

⑦ Transparent LED display

Transparent GOB LED screens ensure a high level of transparency while still providing perfect visual effects.

For traditional transparent LED screens, the PCB board can be easily damaged. But the GOB technology provides better protection for the whole module.

⑧ Small Pixel GOB LED Display

For indoor LED display applications, small-pixel LED displays are now mainstream, especially P1.2 and P1.5 small-pixel LED screens.

However, since LEDs are small, they are relatively fragile, therefore they can easily damage edges and surfaces. Once the small LEDs are broken, it is very difficult to maintain them.

As a result, GOB LEDs are more popular than ever in this field because they have better resistance to pressure, water, and dust, while still being perfectly flat and seamless.

7.2 The use scenario of GOB LED screen.

GOB LEDs can be used both indoors and outdoors, and are obviously more widely used in indoor applications.

The main purpose of developing this technology is for the display to improve its protection and durability against damage from the outside.

As a result, GOB LED displays are highly protective and can act as advertising LED screens and interactive LED screens in a variety of applications.

For example, elevators, shopping malls, fitness rooms, auditoriums, conference halls, live performances, subways, events, studios, concerts, and more.

Its usage scenarios include but are not limited to stage background, command, and control, exhibition, monitoring, advertising, interactive, etc.

By choosing a GOB LED display, you can have a multi-functional assistant to interact with and impress the audience.

Part 8 - How to maintain GOB LEDs?

How to maintain GOB LEDs?

It is not complicated. Maintenance can be achieved within a few steps.

- Figure out the location of the dead pixel.

- Heat the area of the dead pixel with a heat gun, and thaw and remove the glue.

- Apply solder paste to the bottom of the new LED bead.

- Place the beads properly in the correct position (pay attention to the orientation of the light bulbs and make sure the positive and negative terminals are connected in the correct way).

We offer you a comprehensive LED display troubleshooting guide to deal with LED modules and LED display problems.

All you need is to click on how to repair the LED display.

Part 9- Conclusion

To sum up.

GOB process not only solves the problems of product weathering, moisture-proof, water-proof, dust-proof, impact-proof, bump-proof, anti-static, anti-oxidation, lamp bead heat dissipation, anti-blue radiation, anti-UV, and so on.

It also achieves the transformation from a point light source to a surface light source. The product’s luminescence is more uniform, the view angle of the product is greatly improved (horizontal view angle and vertical view angle can reach nearly 180 degrees), and the moiré pattern is effectively eliminated.

The matte effect improves the contrast of the product, reduces glare and blinding sensation, and reduces visual fatigue. For the safety and health of users, the GOB LED display makes effective protection.

Get You Quote Now

With Excellent Products As The Source, Royal Display Factory As The Foundation, Continue To Offer ODM&OEM Service For 10 Years. Please feel free to contact us at any time, we will respond to you in 24 hours.